Metal Foundry topics placed in a clear article

The Significance of Steel Shops: A Detailed Summary of Their Effect On Manufacturing

Steel factories are important to the production landscape. They transform resources right into components that offer varied sectors, from automobile to aerospace. Their competence in alloy solution and spreading strategies assures the production of durable parts. Nonetheless, the industry faces challenges that can improve its future. Comprehending these characteristics exposes real value of shops in technical and financial contexts. What exists in advance for this important industry?

The Duty of Steel Factories in the Production Process

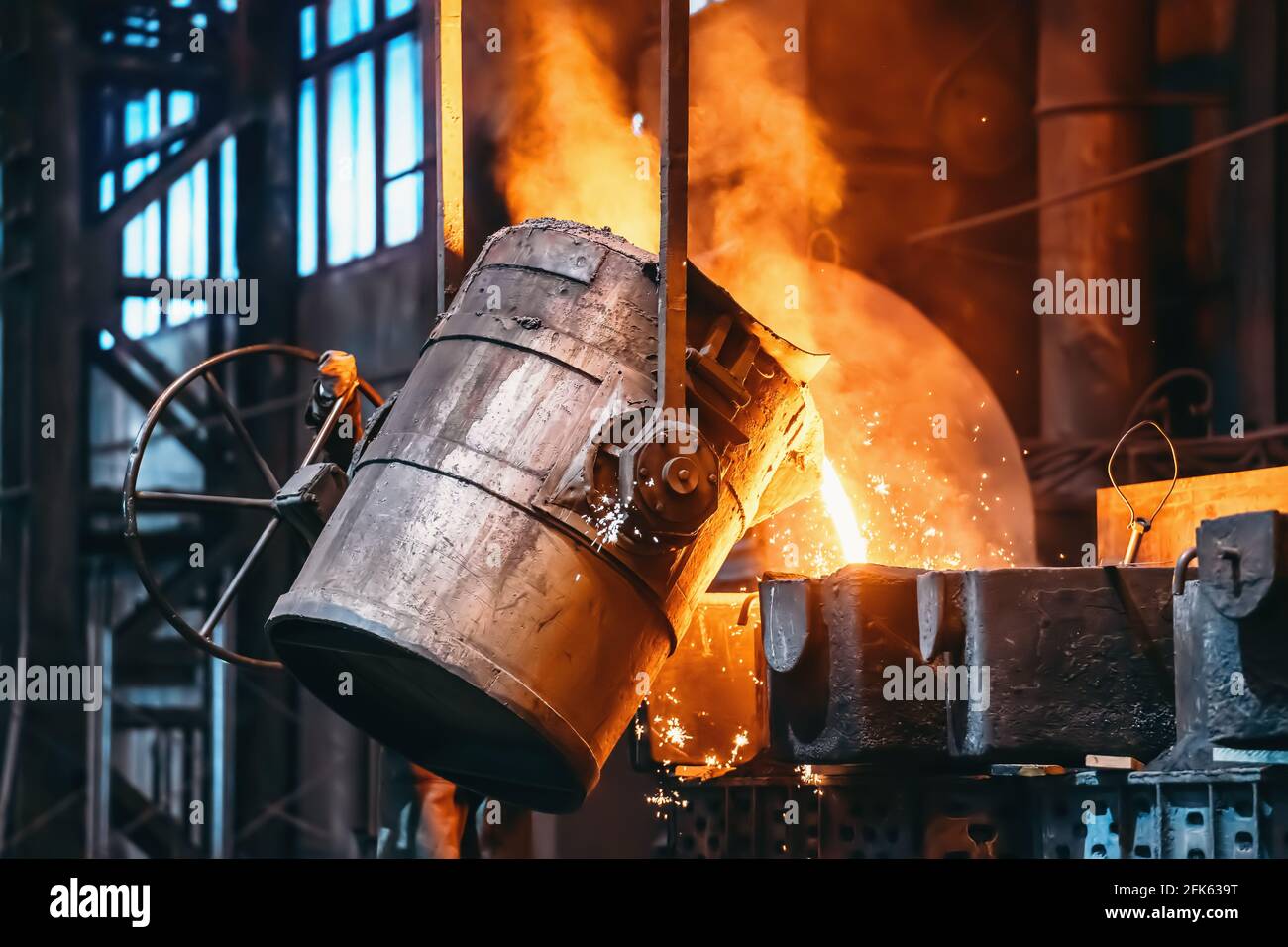

Although often forgotten, metal shops play a vital function in the manufacturing process by transforming raw steels into usable components. These facilities focus on melting numerous metals, such as aluminum, bronze, and iron, and putting them right into molds to produce components for varied sectors. The process starts with the cautious option of resources, making certain that just the highest top quality steels are used. Once thawed, the metal takes on the shape of the mold and mildew, strengthening right into parts that fulfill details style and efficiency criteria.

Metal factories add significantly to sectors like automobile, aerospace, and building by giving necessary components such as engine blocks, equipments, and structural assistances. Their competence in alloy formulation and casting strategies makes it possible for manufacturers to produce detailed layouts while keeping stamina and toughness. Steel shops not just promote the creation of vital parts yet additionally boost the total performance and functionality of modern manufacturing.

Enhancing Production Efficiency With Advanced Techniques

Steel shops are increasingly taking on sophisticated techniques to boost production performance and fulfill the growing demands of different sectors. The application of automation and robotics has structured procedures, decreasing hands-on labor and increasing accuracy in metal spreading operations. Additionally, the assimilation of computer-aided layout (CAD) and simulation software program enables for much better planning and optimization of production workflows, reducing waste and decreasing preparations.

Lean producing concepts are additionally being employed to get rid of inadequacies and boost resource usage. Foundries are now concentrating on energy-efficient methods, such as utilizing waste warm recovery systems, which even more add to set you back financial savings and ecological sustainability. By welcoming these innovative methods, metal factories are not just boosting their operational efficiency yet additionally improving product quality, bring about better client contentment. As markets proceed to evolve, the ability of foundries to adapt to these innovations will certainly be crucial for preserving competitiveness on the market.

Advancements in Metal Casting Technology

As the demand for accuracy and effectiveness in making expands, advancements in metal casting technology are changing the industry landscape. Advancements such as 3D printing and computer-aided design (CAD) are allowing shops to create intricate geometries with better precision and rate. These techniques lessen product waste and lower lead times, cultivating a more lasting production procedure.

Smart factory modern technologies, consisting of the Internet of Things (IoT), help with real-time surveillance and information evaluation, optimizing manufacturing efficiency and reducing downtime. Collectively, these technologies are not only boosting the capacities of steel factories but also setting the phase for the future of production, characterized by boosted dexterity and responsiveness to market demands.

The Economic Impact of Steel Foundries on Neighborhood and Worldwide Markets

Steel shops play a crucial function in forming economic landscapes, both in your area and worldwide. They create significant job development opportunities and add to export and trade, bolstering general economic development. Furthermore, foundries sustain neighborhood business environments, promoting interdependent partnerships that improve neighborhood resilience.

Work Production Opportunities

Work creation in the steel foundry market considerably affects both regional and worldwide economic climates. These facilities give various employment possibility throughout various ability degrees, from skilled labor to engineering and management settings. The need for metal elements in sectors such as vehicle, aerospace, and building drives the requirement for a durable labor force. As metal foundries broaden, they promote added task production in ancillary industries, including transport, logistics, and supply chain monitoring. Furthermore, the economic security given by factory work contributes to local neighborhoods through boosted investing and investment in infrastructure. In general, the metal shop industry's capability to develop work not just boosts private livelihoods however likewise reinforces regional growth and resilience, showcasing its critical duty in financial growth.

Export and Trade Contributions

A significant portion of the financial effect created by shops comes from their payments to trade and export. Metal shops play an important duty in providing parts for various markets, consisting of vehicle, aerospace, and construction, consequently boosting a nation's export capabilities. By producing top notch castings and parts, foundries enable regional economic climates to contend on a global range. The export of these items not only increases profits yet likewise discover this info here promotes international collaborations and trade arrangements. Furthermore, foundries contribute to a positive trade equilibrium, which is important for financial stability. The export tasks of metal shops promote innovation and investment, ultimately reinforcing their importance in both international and local markets, driving growth and financial durability.

Citizen Organization Assistance Solutions

While neighborhood economic climates commonly benefit from the presence of steel foundries, their influence expands beyond mere job development. These facilities add considerably to local business support group by promoting a network of providers, company, and supplementary sectors. This interconnected ecological community boosts economic durability, permitting smaller sized businesses to prosper alongside bigger foundries. Additionally, steel shops typically participate in neighborhood initiatives, buying neighborhood facilities and education and learning, which additionally promotes economic growth. On a wider scale, the presence of shops can draw in financial investment and skill, reinforcing the region's competitive advantage in international markets. Inevitably, the financial payments of steel foundries not only create direct work but also grow a supportive environment for varied local business.

Difficulties Dealing With Metal Factories in the Modern Era

As the steel factory sector advances, it encounters countless challenges that intimidate its sustainability and competitiveness. One considerable problem is the raising expense of raw products, which directly affects manufacturing expenses. Worldwide supply chain disruptions even more exacerbate this problem, making it tough for factories to keep regular operations. In addition, labor scarcities present a substantial obstacle, as competent employees become limited in a quickly transforming technological landscape.

Furthermore, steel factories should emulate strict ecological laws that demand higher conformity expenses and financial investment in cleaner innovations. This change calls for shops to adapt rapidly, usually stressing funds.

Competition check these guys out from automated production procedures and overseas manufacturing adds stress, compeling neighborhood factories to innovate or take the chance of obsolescence. Addressing these difficulties is essential for the industry to flourish in a significantly complicated and competitive market environment.

Sustainability Practices in Steel Founding

In feedback to the obstacles faced by the sector, metal foundries are progressively embracing sustainability techniques to improve their operational efficiency and ecological obligation. These methods consist of the execution of energy-efficient modern technologies, such as electrical induction furnaces, which lower power intake and greenhouse gas emissions. Furthermore, numerous shops are focusing on recycling scrap metal, decreasing waste, and utilizing environmentally friendly materials to decrease their environmental footprint.

Water preservation measures are additionally being focused on, with systems created to reuse process water, therefore lowering freshwater usage. Shops are investing in worker training programs to advertise lasting practices among workers, cultivating a society of environmental recognition.

Future Trends in the Metal Foundry Market

Emerging modern technologies and changing market demands are poised to improve the steel factory industry in the coming years. Enhancing automation, driven by developments in robotics and artificial knowledge, is expected to boost manufacturing efficiency and reduce labor costs. Aluminum Foundry. Additionally, additive manufacturing techniques, such as 3D printing, are gaining traction, permitting more complex and tailored metal components with reduced waste

Sustainability will likewise play an important duty, with factories adopting greener techniques to reduce their environmental impact. The market is most likely to see a surge in the usage of recycled products as raw inputs, straightening with global sustainability objectives.

Additionally, the need for light-weight and high-performance alloys, especially in the aerospace and vehicle sectors, is prepared for to enhance. This advancement will necessitate recurring financial investment in r & d, enabling steel factories to grow and adjust in a competitive landscape. On the whole, these fads are readied to redefine the operational landscape of steel shops.

Regularly Asked Questions

What Types of Metals Are Generally Used in Factories?

Usual metals made use of in foundries include iron, aluminum, zinc, and copper. These products are preferred for their one-of-a-kind residential or commercial properties, making it possible for diverse applications in sectors such as auto, aerospace, and construction, contributing significantly to manufacturing processes.

Exactly How Do Metal Foundries Make Sure Item High Quality and Consistency?

Metal factories guarantee product high quality and uniformity with extensive top quality control procedures, including exact temperature level policy, product screening, and adherence to industry criteria. Normal inspections and competent craftsmanship even more improve dependability and uniformity in production procedures.

What Precaution Are Executed in Metal Factories?

Steel foundries implement precaution such as individual protective devices, ventilation systems, routine security training, and rigorous adherence to security procedures to minimize risks. These methods aim to shield employees look at these guys and preserve a secure workplace.

What Are the Career Opportunities in the Metal Factory Market?

Career chances in the metal foundry sector include duties such as factory workers, quality assurance examiners, designers, maker operators, and management positions. These duties require numerous abilities, offering pathways for development and field of expertise within the field.

Exactly How Do Factories Manage Waste and Recycling of Products?

Shops manage waste and recycling through procedures like redeeming sand, melting scrap steel, and utilizing spin-offs for energy. These techniques minimize environmental effect while advertising sustainability within the metal spreading sector and enhancing resource effectiveness.

Usually overlooked, steel factories play an essential duty in the manufacturing procedure by changing raw metals right into usable components. Metal foundries are significantly embracing innovative strategies to improve manufacturing performance and meet the growing needs of numerous markets. Steel foundries play a vital function in supplying components for numerous markets, consisting of vehicle, aerospace, and construction, thus improving a country's export abilities. In reaction to the challenges faced by the sector, metal shops are progressively taking on sustainability techniques to improve their functional performance and environmental obligation. Aluminum Casting. Job possibilities in the steel factory sector include roles such as factory employees, top quality control assessors, designers, maker drivers, and administration settings